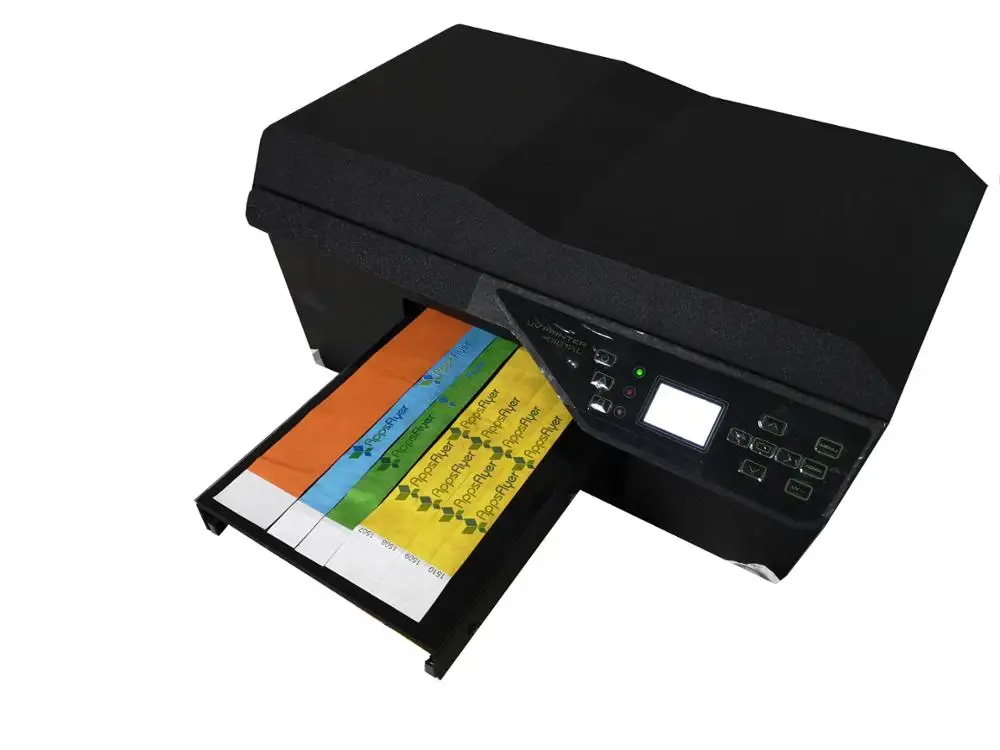

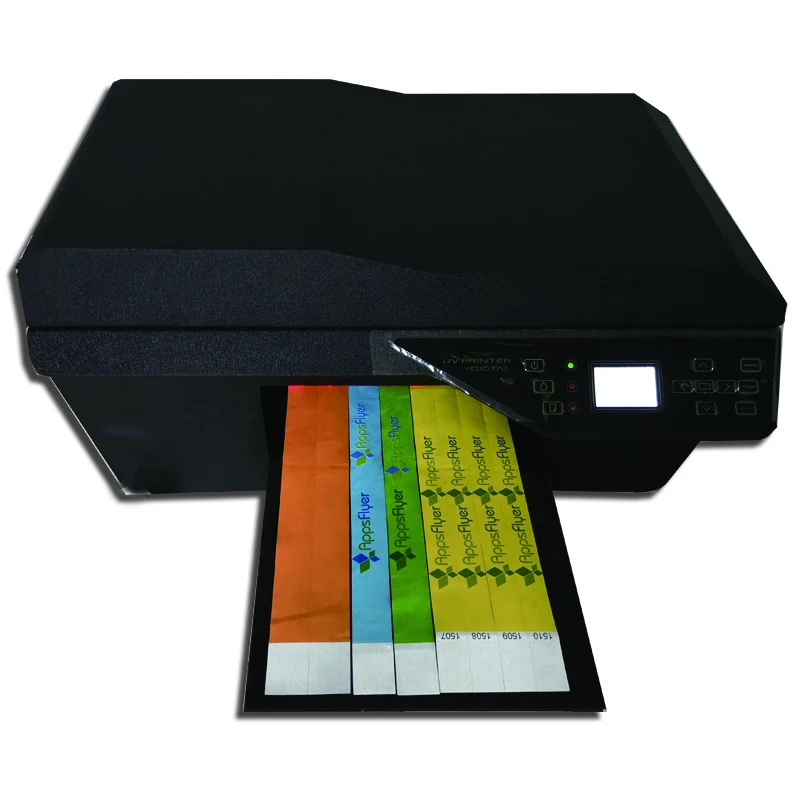

New model AMJ L800 tyvek wristband uv printer

Print your phone case!!! Build your store!!! Make your business!!!

Free online training!!! Free teamviewer support!!! Free lifetime guide!!!

| Print size: A4 size 210mm * 297mm |

| Print head: piezo inkject 1440Nozzles |

| Print color: 6 color C M Y K W W |

| Printing Direction: Bidirectional Printing |

| Printing speed: A4(1440 dpi) /3min |

| Max. height of object : 6cm |

| Max. printing weight: Nondestructive weight 15KG |

| Max printing precision: 2880 dpi * 1440 dpi |

| Ink tank volume: 120ML |

| Height adjustment: Automatic / Manual |

| Height Detection: Automatic / Manual |

| Nozzle protection: Automatic Touch Detection |

| Power : 110-220v 50-60HZ 75W |

| Printing interface: USB 2.0/IEEE1394 |

| Operation system: Windows |

| Working environment: 10-35C, 20-80RH |

| Net weight/ Gross weight : 25KG/ 30KG |

| Printer size: 550mm*520mm*380mm |

AMJ L800 UV Printer: Start to Finish manual Video

Watch the AMJ L800 UV Printer video to know how easy it is to print your own case

Part 1. AMJ L800 A4 UV Printer. Buttons Introducation

Part 2. AMJ L800 A4 UV Printer. Install printer driver and RIP software

Part 3. AMJ L800 A4 UV Printer. Filling ink and Routing Maintenance

Part 4. AMJ L800 A4 UV Printer. How to print

inquiry for the video link

Why Choose AMJ L800 UV printer?

The AMJ L800 UV Printer offers a complete design and UV printing package, Professional RIP software

SUPERIOR GARMENT PRINT QUALITY

Purpose-built print head, ink, and printer mechanism – produces outstanding print quality

HIGH-PERFORMANCE PRINTED PRODUCTION

One of the best UV printers in it’s price class – runs all day with little downtime

SUPERIOR PRINTER RELIABILITY

Developed specifically for high-performance, directto phone case printing, no need coating and ink dry immediately after printing

AMJ L800 UV Printer Features

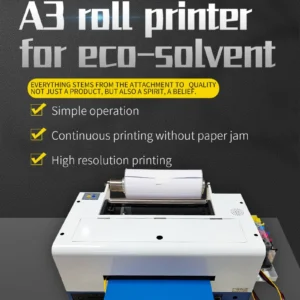

For over seven years developed from eco solvent ink printer dedicated a team of mechanical, chemical, and software engineers to create an all new UV printing technology dedicated for printing directly to phone case and other materials.

- All-New High-Density UV ink Printing

- Precision dot control for extreme print clarity and sharpness and embossed result

- By utilizing more advanced piezo materials, a higher-level of print head durability is achieved

- High-Precision MEMS Manufacturing Process

- Based on the Micro-Electro-Mechanical Systems process for an unparalleled level of manufacturing efficiency for consistent production quality

- Outstanding Ink Flexibility

- The RIP Softwareis capable of printing with a wide-range of ink types

UV Ink CISS

UV Ink CISS

- Internally Developed by Epson

- high quliaty uv ink , no need pretreatment liquid coating

- Ink dry immediately after printing

- Developed together with the print head technology to improve overall reliability

- Outstanding Color Performance

- Clean, bright, accurate color for outstanding finished

- Next-Generation White Ink Technology

- New high-dispersion ink technology helps to reduce white ink sedimentation

- Very high white ink density, with a very natural white color

- Free Workflow Software RIP

- RIP software application supporting – JPEG, TIFF, PNG, and BMP graphic files

- For free providing

- Easy-to-Use Layout

- Choose your platen size, place your image file, position, scale, rotate, etc. – then print

- Very simple interface – quick learning-curve

- Robust Color and White Ink Control

- Independent controls for color and white imaging – even on the same materials

- Powerful color adjustment features

Automatic

Automatic height adjustment

- User-Adjustable Platen Height Setting

- Printer automatically verifies the surface height of the materials before printing.

- This system allows for faster load times and more reliable everyday production.

- General Printer Maintenance Routine

- Print the internal print head Nozzle Check pattern to verify nozzle health – once per day

- If required, perform an automatic Print Head Cleaning cycle – ink is use

- When instructed by the printer, replace the Print Head Capping Station, Print Head Fabric Wiper, and Print Head Flushing Pad – replaced after approximately 3-6 month

- As required, clean the Print Head Cleaning Cap – about once per week

- White Ink Maintenance Routine

- When instructed, remove the white ink cartridges and Shake them – once per day

- When instructed, perform a White Ink Flushing – about once per month – ink is used

- Color Ink Maintenance Routine

- When instructed, remove the color ink cartridges and Shake them – about once per month

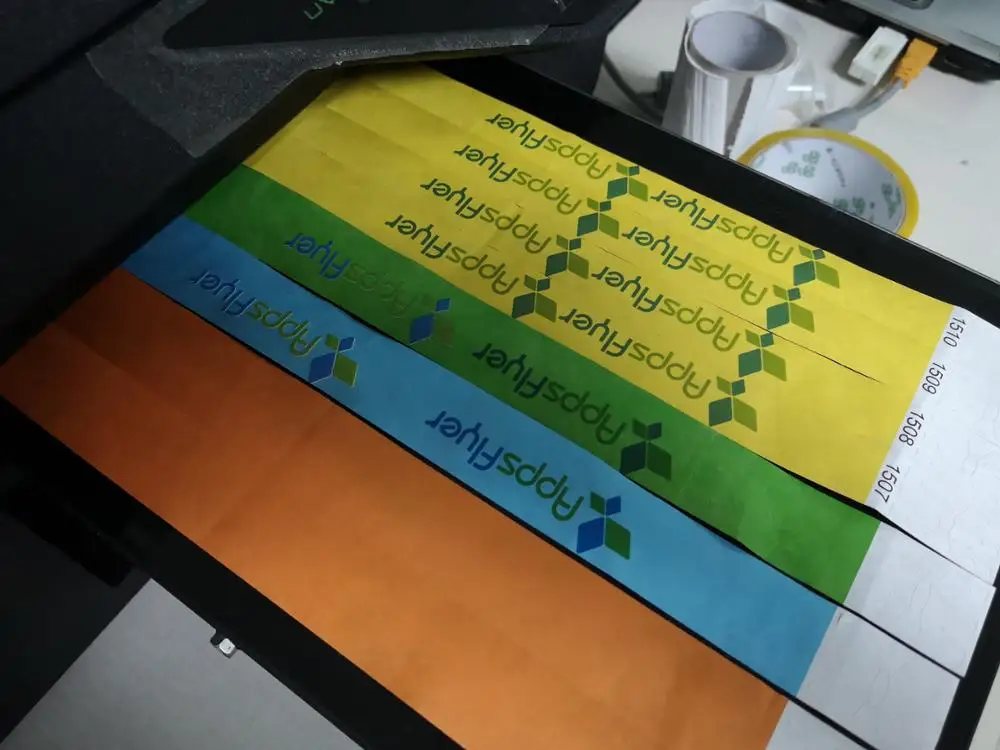

Customer show

Others Printing sample show

Factory show![AMJ L800 A4 UV [00_00_14][20170509-102842-0].JPG](http://sc01.alicdn.com/kf/HTB1RnRNRXXXXXbAXpXXq6xXFXXXx/202220655/HTB1RnRNRXXXXXbAXpXXq6xXFXXXx.jpg)

![AMJ L800 A4 UV [00_00_17][20170509-102946-3].JPG](http://sc02.alicdn.com/kf/HTB18wNHRXXXXXbSXFXXq6xXFXXXs/202220655/HTB18wNHRXXXXXbSXFXXq6xXFXXXs.jpg)

Package and shipping

Our certificate

Please contact us for more information

For more information and better price, Please inquiry and Click the “send“!!!

Reviews

There are no reviews yet.